The Rise of 3D Printing: Innovations and Applications

3D printing is revolutionizing industries from healthcare to aerospace, driving innovation and enabling new applications across various sectors.

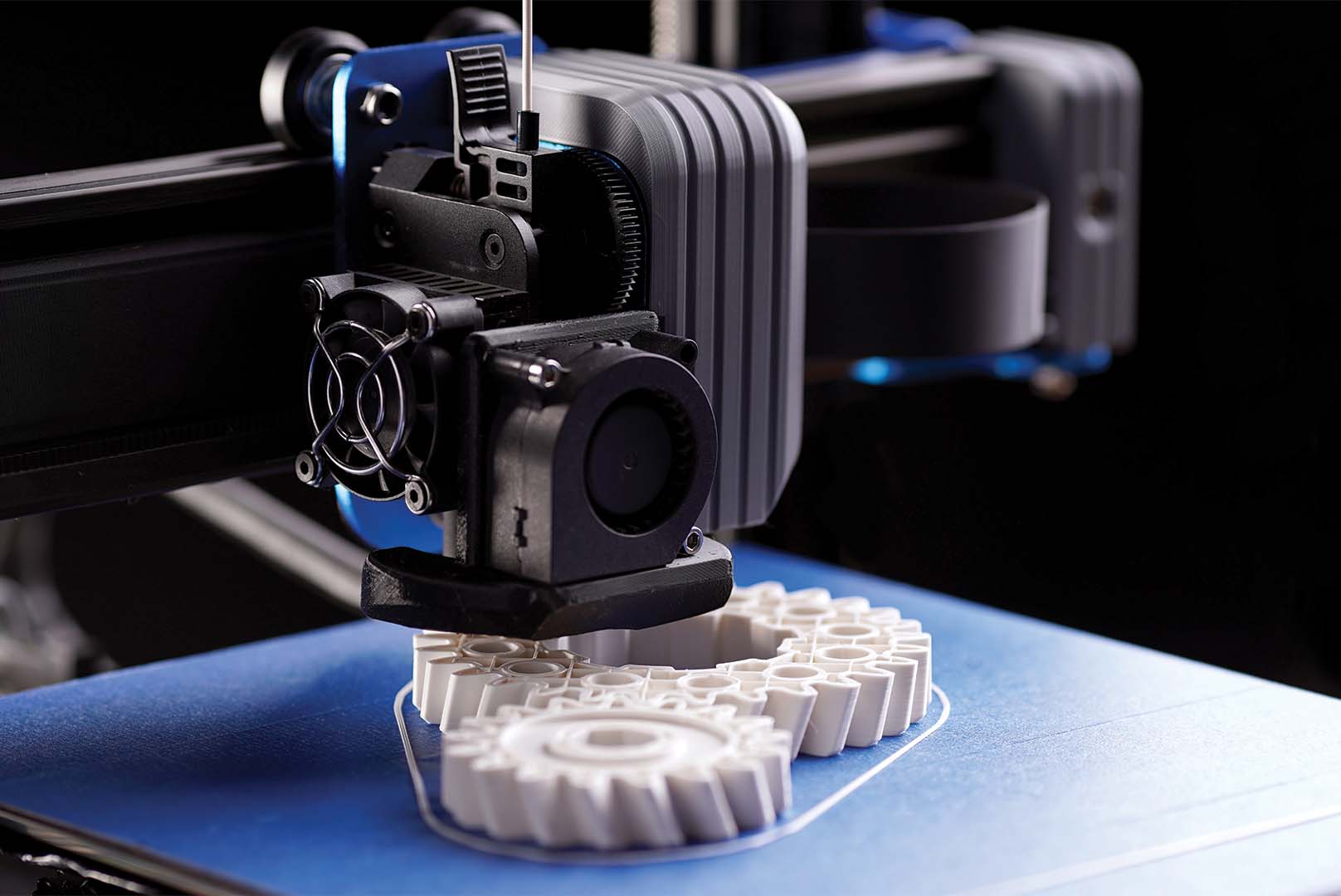

The Advent of 3D Printing Technology

The 3D printing revolution has fundamentally transformed the landscape of manufacturing and design. By enabling the creation of complex structures layer by layer, 3D printing bypasses many of the limitations of traditional manufacturing methods. This technology, also known as additive manufacturing, uses digital files to produce three-dimensional objects, often utilizing materials such as plastics, metals, and ceramics. The versatility of 3D printing allows for rapid prototyping, reducing the time and cost associated with product development. This has opened up new avenues for innovation across various industries, from healthcare to aerospace, making it a pivotal force in modern manufacturing.

Innovations in Material Science

One of the most significant advancements in 3D printing has been the development of new materials. Initially, 3D printers were limited to simple plastics, but recent innovations have expanded the range of printable materials to include biodegradable polymers, metal alloys, and even biomaterials. This has allowed for the creation of more durable and functional products. For example, the medical field has seen the emergence of biocompatible materials that can be used for implants and prosthetics. The continuous improvement in material science is pushing the boundaries of what can be achieved with 3D printing, making it an ever-evolving field with immense potential.

Transforming Healthcare and Medicine

The healthcare industry has been one of the biggest beneficiaries of 3D printing technology. Customizable prosthetics and implants are now more accessible and affordable, improving the quality of life for many patients. Surgeons can use 3D printed models of organs and bones to plan complex surgeries with greater precision. Additionally, the development of bioprinting—the use of 3D printing technology to create tissues and organs—holds promise for the future of organ transplantation. By using a patient's own cells, bioprinting could potentially eliminate the issues of organ rejection and donor shortages, marking a significant leap forward in medical science.

Impact on Manufacturing and Industry

In the realm of manufacturing, 3D printing has introduced a new level of efficiency and flexibility. Traditional manufacturing processes often involve multiple steps and significant waste, but 3D printing streamlines production by creating objects directly from digital designs. This not only reduces material waste but also allows for the production of highly complex and customized components. Industries such as automotive, aerospace, and consumer electronics are leveraging 3D printing to produce parts that are lighter, stronger, and more efficient. The ability to quickly iterate and prototype designs has also accelerated innovation, making it easier for companies to bring new products to market.

The Future of 3D Printing

As 3D printing technology continues to evolve, its applications are expected to expand even further. Home 3D printers are becoming more affordable, allowing hobbyists and small businesses to create custom products from the comfort of their homes. In education, 3D printing is being used to teach students about engineering, design, and manufacturing processes. The potential for sustainability is another exciting aspect, as 3D printing can utilize recycled materials and reduce waste. With ongoing advancements in speed, precision, and material capabilities, the future of 3D printing holds limitless possibilities, promising to reshape industries and redefine the way we create and consume products.